Shanghai Bestcomp Compressor Co., Ltd.

Shanghai Bestcomp Compressor Co., Ltd.

AIRERA issued the New edition 2-stages air compressors as the new member of our Compressed Air Systems.

There is a growing demand for reliable, energy-efficient compressed air.

You can benefit from a two-stage rotary air compressor. AIRERA AGCD-II 2-stges compressors are designed with efficiency, reliability, and optimization in mind.

Many industries that require low pressure air still use screw air compressors with a pressure range of 0.3-0.5 MPa, to save significant amount of electricity by using pressure reducing valves to meet the requirements of compressed air usage.

In response to the call for energy conservation and emission reduction.

AIRERA developed low pressure screw air compressor based on market demand.

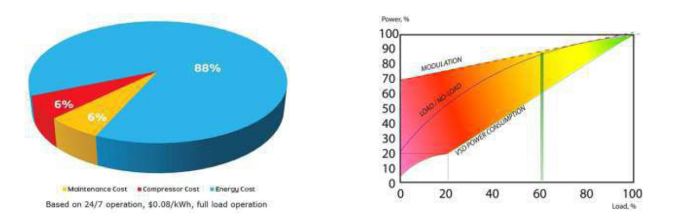

Factor Power Costs into Purchasing Decision

Power costs represent up to 80% ofthe total cost ofownership ofa rotaryscrew air compressor.and the energy savings over the life ofa two-stage air compressor can be significant.

The efficiency differences ofsingle-stage and two-stage air compressors using load/unload,modulation, and Variable Speed Drive methods of control at any particular point on the power curve.

Top reliability

Advanced design and high-quality materials to reduced environmental impact at the low noise levels.

Reliable operation in hot and dusty environments IP55/65 Motor, large oversized cooler blocks for harsh working environment.

The higher efficiency

Two-stage AIRERA compressors provide a higher level of efficiency than single-stage compressors, making them more useful for a variety of tasks.

It reaches GB first-class energy-saving performance standard energy usage to save you money.

Easy maintenance

We design our two-stage compressors with fewer components and a simpler design compared to single-stage compressors drastically reduce your maintenance requirements.

easy access for repairs as well as a specialized sound-deadening enclosure, the latter of which minimizes operating noise.

New ROLLING PROFILE® – ultimate efficiency with reduced noise

| AGCD-II Series dual stage screw air compressor | |||||||||

| #NAME? | Capacity m3/min | Power | Weight | Noise | Dimension/ | ||||

| 7 bar | 8 bar | 10 bar | 13 bar | (KW) | Kg | dB(A) | L×W×H(mm) | ||

| AGCD-15II * | 2.77 | 2.76 | - | - | 15 | 370 | 67±3 | 1260×700×1200 | G1 |

| AGCD-18.5II* | 3.47 | 3.45 | 2.72 | 2.60 | 18.5 | 405 | 70±3 | 1400×850×1200 | G1 |

| AGCD-22II* | 4.13 | 4.10 | 3.40 | 2.68 | 22 | 470 | 70±3 | 1400×850×1200 | G1 |

| AGCD-30II* | 5.94 | 5.89 | 4.50 | 3.92 | 30 | 715 | 72±3 | 1400×1000×1300 | G1-1/2 |

| AGCD-37II* | 7.09 | 7.06 | 7.01 | 5.55 | 37 | 785 | 72±3 | 1400×1000×1300 | G1-1/2 |

| AGCD-45II* | 9.08 | 9.06 | 7.30 | 6.84 | 45 | 820 | 73±3 | 1400×1000×1300 | G1-1/2 |

| AGCD-55II* | 12.10 | 11.50 | 9.32 | 7.80 | 55 | 1200 | 75±3 | 1850×1300×1450 | G2 |

| AGCD-75II* | 15.20 | 15.15 | 12.50 | 11.85 | 75 | 1400 | 75±3 | 1850×1300×1450 | G2 |

| AGCD-90II* | 19.30 | 18.90 | 15.86 | 14.98 | 90 | 1570 | 75±3 | 2100×1300×1450 | G2 |

| AGCD-110II* | 24.86 | 22.50 | 19.50 | 16.50 | 110 | 1760 | 78±3 | 2540×1640×1800 | G2-1/2 |

| AGCD-132II* | 26.90 | 26.50 | 24.00 | 19.50 | 132 | 2200 | 78±3 | 2540×1640×1800 | G2-1/2 |

| AGCD-160II* | 32.80 | 31.50 | 28.80 | 26.40 | 160 | 2400 | 78±3 | 2540×1640×1800 | G2-1/2 |

| AGCD-185II* | 43.85 | 39.50 | 32.90 | 27.90 | 185 | 2800 | 78±3 | 3150×1800×2100 | G2-1/2 |

| AGCD-200II* | 45.90 | 45.30 | 39.40 | 34.90 | 200 | 3300 | 78±3 | 3150×1800×2100 | DN80 |

| AGCD-250II* | 53.45 | 51.50 | 44.50 | 39.70 | 250 | 3600 | 78±3 | 3150×1800×2100 | DN80 |

| AGCD-280II* | 56.45 | 55.50 | 50.90 | 43.50 | 280 | 5700 | 79±3 | 3450×2000×2200 | DN100 |

| AGCD-315II* | 63.95 | 63.50 | 56.90 | 49.90 | 315 | 6800 | 79±3 | 3450×2000×2200 | DN100 |

| AGCD-355II* | 72.90 | 72.60 | 60.90 | 54.98 | 355 | 8500 | 79±3 | 4000×2050×2200 | DN150 |

| AGCD-400II* | 85.40 | 81.90 | 72.40 | 64.80 | 400 | 11500 | 79±3 | 4500×2500×2200 | DN150 |

| AGCD-450II* | 95.40 | 91.90 | 82.40 | 74.80 | 450 | 12500 | 79±3 | 4500×2500×2200 | DN150 |

| AGCD-500II* | 115.90 | 108.90 | 101.45 | 84.80 | 500 | 12900 | 79±3 | 4500×2500×2200 | DN200 |

| AGCD-560II* | 119.90 | 115.70 | 93.50 | 89.80 | 560 | 13500 | 79±3 | 4500×2500×2200 | DN200 |